Our Products

Built to Perform. Made to Last.

Whether exposed to heat, dust, oil, or intense vibration, Toyopower belts are engineered to endure. Wherever machinery demands smooth, quiet operation at high speeds, our solutions deliver lasting precision. From heavy-duty applications to compact systems, Toyopower products are designed to perform reliably—no matter the load, speed, or conditions

- Select Product

- ALL PRODUCTS

- INDUSTRIAL

- AUTOMOTIVE

- AGRICULTURAL

Automotive Timing Belt

Timing belts are precision-engineered synchronous drive belts designed with accurately molded teeth that engage with matching grooves on pulleys.

Unlike conventional V-belts, timing belts deliver positive, slip-free power transmission, ensuring exact synchronization between driving and driven components.

Key Features:

Precise Power Transmission: Tooth profile ensures accurate timing with no slippage.

High Efficiency: Transmits power with minimal energy loss.

Durability: Made from premium rubber compounds and reinforced with strong tensile cords (e.g., fiberglass, aramid, or steel).

Low Noise Operation: Smooth meshing with pulleys reduces vibration and noise.

Maintenance-Free: Requires no lubrication compared to chain drives.

Operating Temperature Ranges: -30°C to 100°C

Applications:

Automotive engines (camshaft/crankshaft synchronization)

Office automation equipment

Textile and packaging machinery

Agricultural and industrial machinery

Printers, copiers, and precision equipment

Advantages Over Conventional Belts:

Accurate synchronization for timing-critical applications

Longer service life with minimal elongation

Resistance to oil, heat, and wear

Supports compact, lightweight drive designs

Available Types & Sizes:

Profiles: Trapezoidal (MXL, XL, L, H), Curvilinear (HTD, STD, GT)

Materials: Neoprene, EPDM, Polyurethane with fiberglass or aramid cords

Standard and custom lengths available

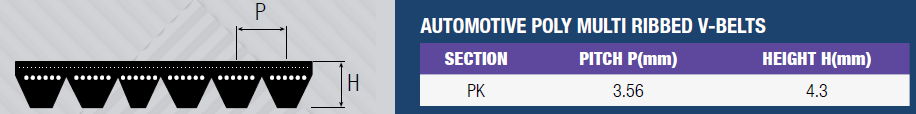

Multi Ribbed

The multi-rib belt, also known as a poly-V belt, is a high-performance drive belt designed for modern automotive engines. It features multiple longitudinal ribs that run along the belt’s length, providing greater surface contact and improved power transmission compared to conventional V-belts.

Key Features:

Compact Design: Enables higher power transmission in limited space.

High Flexibility: Allows use with smaller pulleys and serpentine drive systems.

Durability: Made from advanced EPDM (ethylene-propylene-diene monomer) or CR (chloroprene) compounds for superior heat, oil, and wear resistance.

Low Noise & Vibration: Precision rib profile ensures smooth, quiet operation.

Extended Service Life: Resistant to cracking, glazing, and stretching under extreme conditions.

Operating Temperature Ranges: Chloroprene Rubber(CR): -30°C to 100°C & Ethylene Propylene Diene Monomer(EPDM): -40°C to 140°C

Applications:

Automotive serpentine belt systems

Alternator drives

Air conditioning compressors

Power steering pumps

Water pumps and other auxiliary components

Advantages Over Conventional Belts:

Single belt can drive multiple accessories

Reduced slippage, higher efficiency

Lower maintenance and replacement frequency

Better performance under high-speed and high-load conditions

Available Sizes:

Rib profiles: PK, PJ, PL,PM, etc.

Lengths: Standard and customized sizes available

Standard PK belt (narrow ribbed/poly V-belt)

Non-elastic version – requires manual tension adjustment or self back tensioning

Pulley adjustment is needed with proper belt tension

Elastic PK belt (narrow ribbed/poly V-belt)

Elastic version is stretchable, allowing it to self-tension without tensioning /back tensioning pulley

No pulley adjustment is needed; it adapts automatically to small changes in pulley distance or wear.

Standard PJ belt (narrow ribbed/poly V-belt)

Require proper tensioning during installation.

Application: mostly for washing machine use

Elastic PJ belt (narrow ribbed/poly V-belt)

Stretchable, self-tensioning, easy to install.

Application: mostly for washing machine use

Standard PL belts

Require proper tension adjustment.

Application: Light-duty machines, small industrial equipment, appliances, and compact drives.

Elastic PL belts

Stretchable and self-tensioning, easier installation.

Application: Light-duty machines, small industrial equipment, appliances, and compact drives.

PM Belt (Poly-V / Narrow Rib Heavy-Duty Belt)

PM belts are high-performance narrow-ribbed belts designed for industrial and automotive applications requiring compact drives with high torque transmission. They are ideal for heavy-duty systems where durability, flexibility, and smooth operation are essential.

Laminated

Laminated belts are specially constructed transmission belts made by bonding multiple layers of high-strength fabric and rubber compounds.

This layered construction provides exceptional flexibility, dimensional stability, and high tensile strength, making laminated belts suitable for heavy-duty applications where durability and smooth operation are critical.

Key Features:

Multi-Layer Construction: Ensures uniform load distribution and reduced belt deformation.

High Strength: Reinforced layers provide superior resistance to stretching and heavy loads.

Flexibility: Designed for smooth engagement and operation over a range of pulley diameters.

Durability: Excellent resistance to heat, oil, and wear for extended service life.

Stable Performance: Maintains grip and power transmission efficiency under varying conditions.

Operating Temperature Ranges: -20°C to 80°C(short peaks up to +100°C).

Applications:

Agricultural machinery

Industrial equipment

Automotive heavy-duty applications

Textile and packaging machinery

Power transmission systems requiring high torque

Advantages:

Extended operational life compared to standard belts

Consistent performance under shock loads and variable speeds

Reduced maintenance due to wear resistance

Suitable for high-torque and continuous operation environments

Available Sizes:

Standard widths and lengths available

Custom sizes can be manufactured upon request

Cogged

Cogged belts, also called notched V-belts, are specially engineered to deliver superior flexibility and efficiency compared to conventional smooth V-belts.

The precision-molded cogs on the inner surface reduce bending resistance, allowing the belt to wrap easily around smaller pulleys and dissipate heat more effectively. This results in enhanced power transmission and longer belt life.

Key Features:

High Flexibility: Cogged design enables tighter bend radius, ideal for compact drive layouts.

Increased Efficiency: Reduced slippage and lower heat build-up for stable performance.

Durability: Resistant to cracking, stretching, and glazing under heavy loads.

Improved Grip: Cogs enhance traction for consistent power delivery.

Energy Saving: Lower energy loss compared to conventional V-belts.

Operating Temperature Ranges: -20°C to 80°C(short peaks up to +100°C).

Applications:

Automotive engines (fan belts, alternator drives, power steering, A/C)

Agricultural machinery

Industrial equipment and compressors

Lawn & garden equipment

HVAC systems

Advantages Over Conventional V-Belts:

Runs cooler with less wear

Handles higher speeds and loads

Extended service life

Suitable for smaller pulley diameters

Available Sizes:

Profiles: AX, BX, CX, XPZ, XPA, XPB, etc.

Lengths: Standard and customized sizes available